With corrosion resistance, high strength and durability, 304 stainless steel screen mesh is an important accessory in vibrating sieve screening operations. Especially in the chemical, food, pharmaceutical, mining and other industries, the vibrating screen needs to deal with wet, high temperature or corrosive materials for a long time, 304 stainless steel screen can effectively extend the service life of the screen.

This article will introduce in detail the characteristics of 304 stainless steel screen mesh, the key role in the vibrating screen, and how to choose the right 304 stainless steel screen mesh to optimize the screening effect, to help you improve the production efficiency and reduce the maintenance cost.

Manufacturing Process of 304 Stainless Steel Woven Mesh

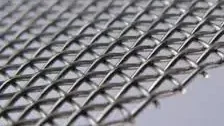

Plain Weave

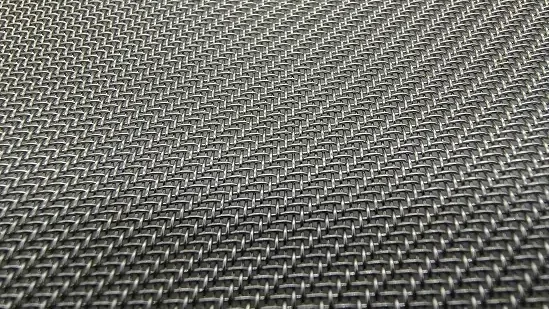

Twill Weave

Each warp thread alternately passes over and under every two weft threads, while each weft thread alternately passes over and under every two warp threads. This enhances mesh flexibility and reduces material clogging.

dense Weave

Warp and weft threads differ in diameter and mesh count, characterized by sparse warp threads and dense weft threads, or coarse warp threads and fine weft threads. The warp runs lengthwise, while the weft runs widthwise. Dense-weave mesh further divides into plain-woven and twill-woven varieties. Screens produced via this technique suit fine screening applications in industries like pharmaceuticals and powder metallurgy.

Additionally, 304 stainless steel woven mesh undergoes electropolishing or electrolytic treatment to enhance surface smoothness, reduce material adhesion, and impart excellent elasticity and wear resistance to the stainless steel wires. Electrolytically treated 304 stainless steel woven mesh resists deformation under prolonged impact from vibrating screens, ensuring stable screening accuracy.