Circular tumbler screen

The difference between the tumbler screen machine and the ordinary vibrating screen: it is an upgraded version of the standard vibrating screen, which has a wider application range, higher output and precision, and less wear and tear on the screen and the machine. Some special materials, such as EPP material, can only Use a Tumbler Screen Machine, of course, the cost of the Tumbler Screen Machine is higher.

tumbler screen Common Applications

Circular tumbler screen experiment

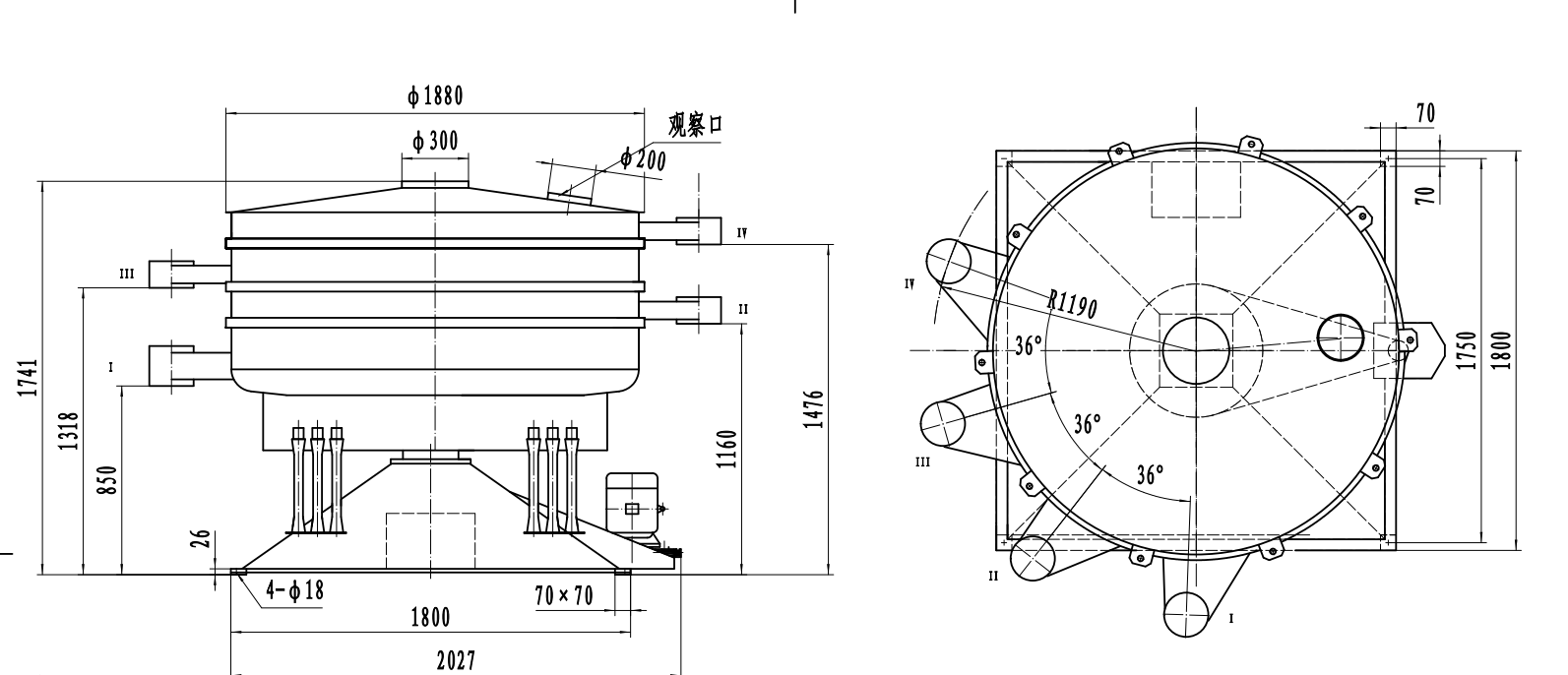

Structure of the Circular tumbler screen

Working principle

The motor drives the eccentric block, and through the special mechanical structure, the material forms an elliptical motion track on the screen, and simultaneously jumps up and down, similar to manual screening. This screening track makes it easier for materials with similar particle specific gravity to be Gathered together, particles with a significant difference in specific gravity are easier to stratify, thereby improving screening efficiency. At the same time, the imitation of artificial movement trajectory makes the screening softer, not destructive vibration.

Product Parameters

| Circular swinging screen model | Motor model | Motor power | Voltage | Motor speed | Equipment material | Number of plies |

|---|---|---|---|---|---|---|

| YBS-1200 | Y100L1-4 | 2.2KW | 220-480V industrial three-phase power | 1500r/min | Q235/304/316L | 1-3 floors |

| YBS-1600 | Y100L2-4 | 3.0KW | 220-480V industrial three-phase power | 1500r/min | Q235/304/316L | 1-3 floors |

| YBS-2000 | Y112M-4 | 4.0KW | 220-480V industrial three-phase power | 1500r/min | Q235/304/316L | 1-3 floors |