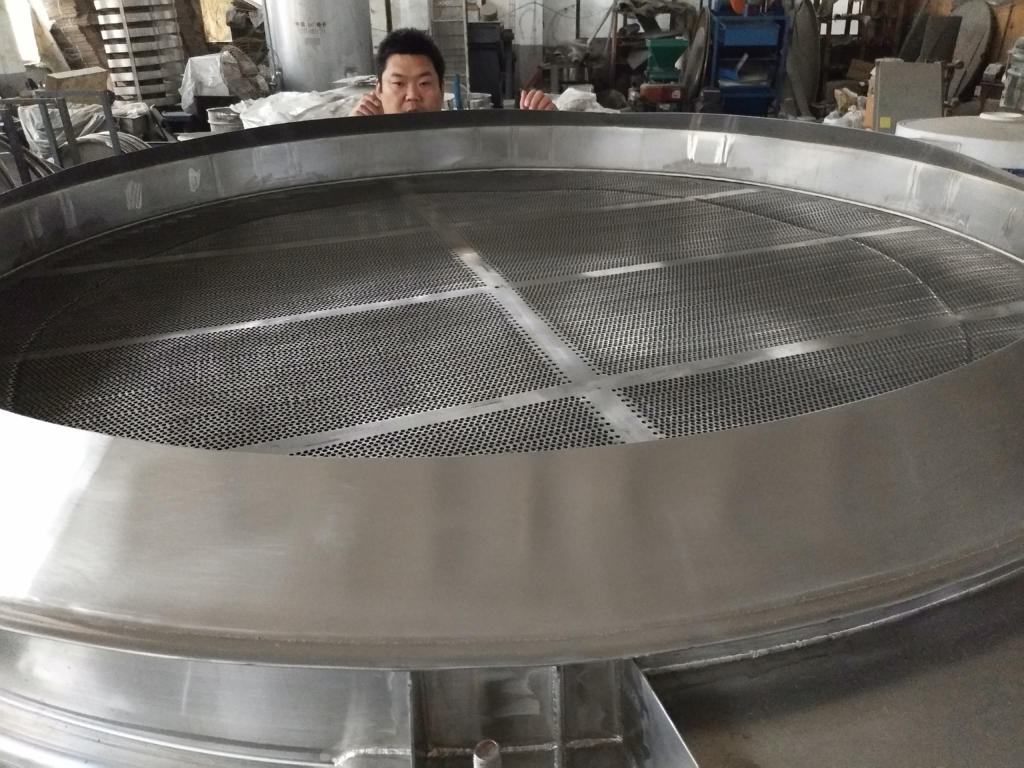

Gyratory Screen: oil fracturing proppant

The function of petroleum fracturing proppant is to crack the oil-gas-bearing rock strata after high closure pressure and low permeability deposits are fractured during oil and gas deep well mining, and oil and gas are collected from the channels formed by the cracks. At this time, fluid is needed Inject into the rock base, with a pressure exceeding the fracture strength of the formation, creating cracks in the rock formation around the wellbore, forming a channel with high-level flow capability, to keep the cracks formed after fracturing open, and oil and gas products can pass through smoothly.

Customer requirements:

- Screening of quartz sand, the screen selected by the customer is a four-layer screen of 20 mesh, 40 mesh, 70 mesh, and 120 mesh

- The screening accuracy is required to be 99%.

- Required production capacity of 30 tons/hour

- The quality of the equipment is required to be stable, simple and easy to operate, and convenient to change the screen

- A supporting testing vibrating screen is required to facilitate subsequent testing of products

Project details

Industry problems: The main screening difficulty of petroleum fracturing proppants lies in the industry. The screened material itself is quartz sand or ceramsite, but it is used as a filler in oil collection, so the accuracy of screening The accuracy requirement is very high, and it needs to reach 99%. Because this needs to be used in large quantities in the oil collection process, the difficulty of screening oil fracturing proppants is both accuracy and output.

Project solution

The solution, the solution given by our company is to choose 6 sets – double-layer Gyratory Screen – 2040 model, which can solve customer problems.

The advantages of Gyratory Screen

Large output: The screen area of the Gyratory Screen is the largest in the field of fine screening at present. The area of its single-layer screen is 2 meters wide and 4 meters long. The square swinging screen can be installed with 8-10 layers of screens, and the maximum screening area is 80 square meters per single device. Such a large screening area is the key factor for him to ensure the output and precision.

Stable quality: The Gyratory Screen adopts hanging equipment. The equipment itself does not produce destructive vibration, but periodically swings, and the service life of the equipment and the screen is greatly increased.

It is convenient to replace the screen, skilled workers, two people can complete it in about 10 minutes

client feedback

Customers are very satisfied with the effect of the square oscillating sieve after using it, so they order our products in large quantities. And in the following two years, the client company expanded again.