External Factors Affecting Screening Effect (2)

For all vibrating sieves (except Test Sieve), to achieve the best screening effect, the way of feeding is very important. Today we only discuss the feeding method. Next, we will discuss it one by one and explain why it affects the screening effect.

First of all, we need to understand the core working principle of all vibrating screens: the powder particles fully contact the screen, the powder particles smaller than the mesh fall, and the powder particles larger than the mesh remains on the screen. These two are the key points.

- The powder particles fully contact the screen.

- Let the powder material cover the entire screen.

The powder material is fully in contact with the screen

This requires uniform feeding, intermittent feeding, and a sudden large amount of feeding when feeding materials.

It will cause the material layer on the sieve to be too thick. As shown in the figure above, only a part of the material fully contacts the sieve, and some materials do not touch the sieve at all, resulting in a poor screening effect. Suddenly no material enters the vibrating screen, and the screen is not working during this period The vibrating screen is running without load.

This leads to a decrease in output per unit of time. As shown above.

Let the material fully contact the screen

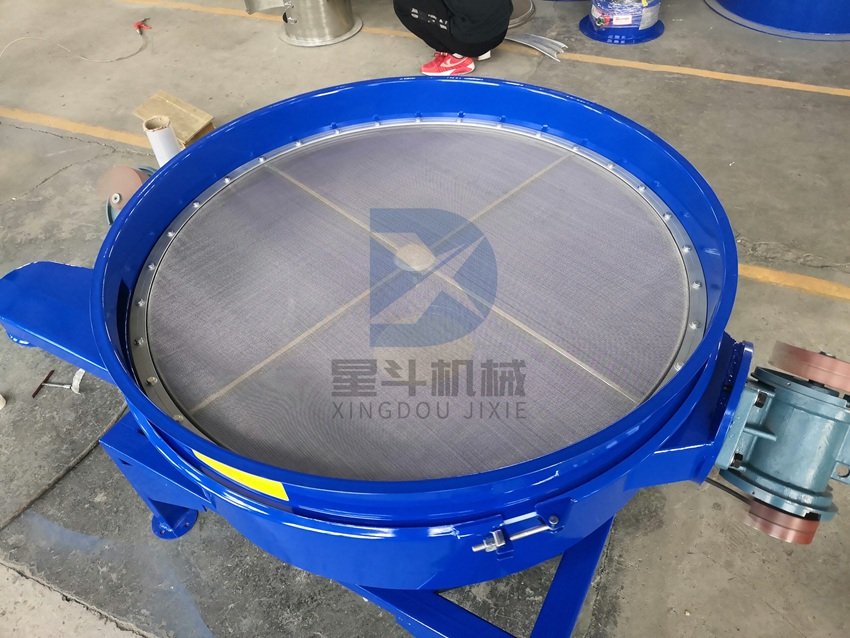

As shown in the picture: most of the materials are concentrated on the right, and the screen on the left is not fully applied, resulting in a decrease in output and precision.

This is the responsibility of our vibrating screen manufacturers. For a good vibrating screen, when screening some materials with relatively high precision requirements, the feeding port of the equipment will be equipped with a material distribution device, so that the screen of the vibrating screen can be fully used. , each piece of equipment in our company will be equipped with a distributor.