Material Screening & Sifting Equipment

Wood Chip Screener Oscillating Screen

Straight Row Sieve

Square Gyratory Screen

Rotary Vibrating Screen

Linear Vibrating Screen

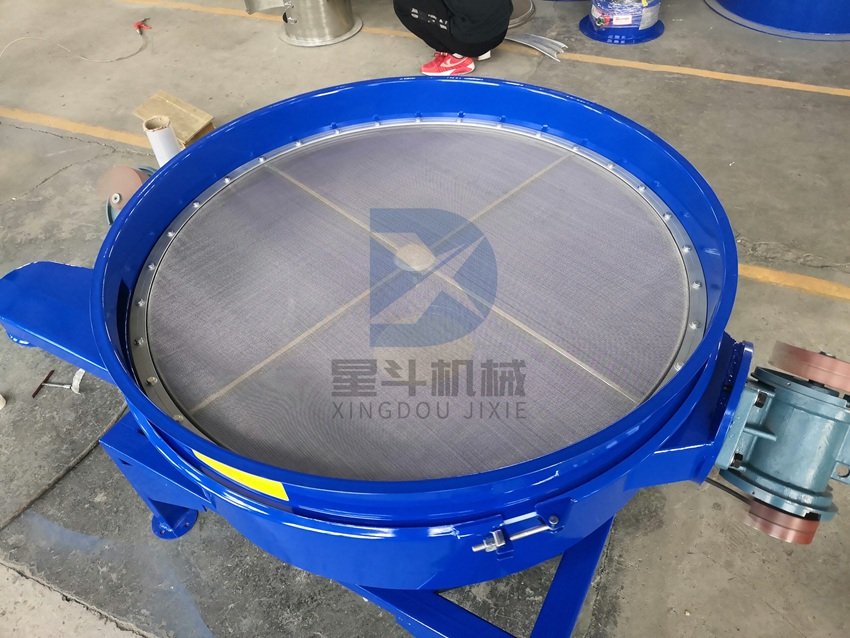

Circular tumbler screen

VIDEO

CASE STUDIES

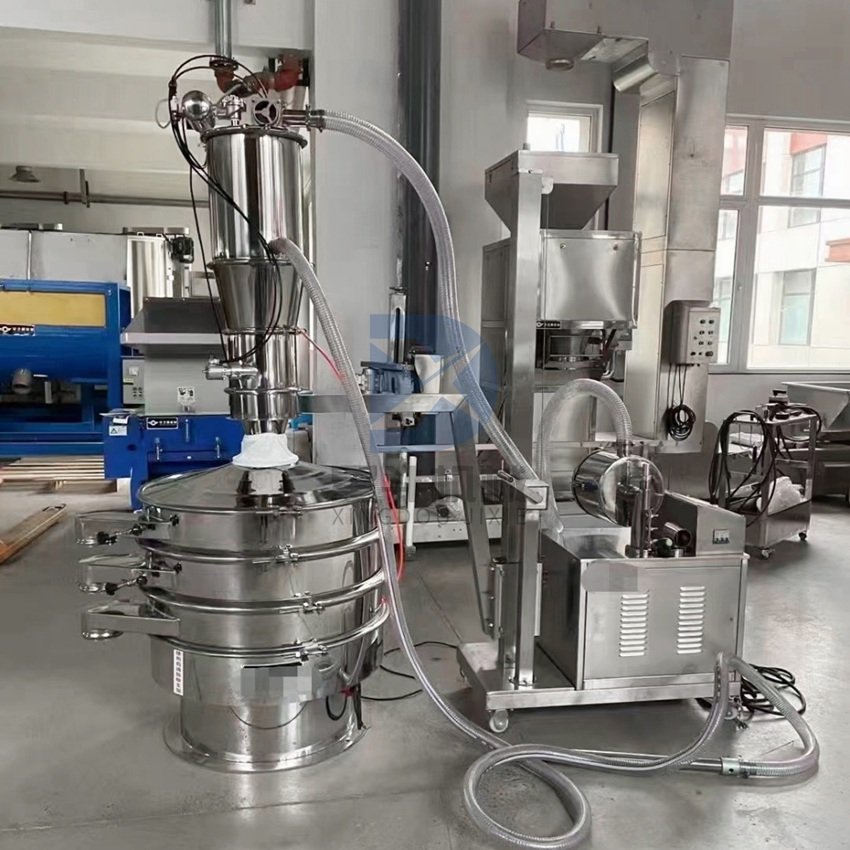

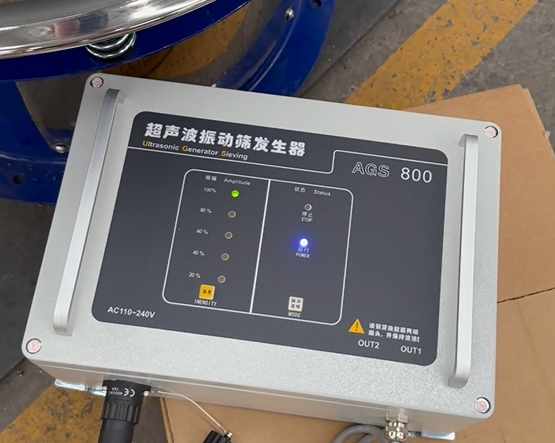

Ultrasonic Vibrating Sieve for Acrylic Powder

Large Out Gyratory Screen Separator For Mica Powder Sieving

Why Choose The Gyratory Screener For Calcium Powder Sifting?

Rotary Vibrating Screen: Solid-Liquid Separation Solution

Spiral Elevator Case: Monosodium Glutamate

Vacuum Feeder Machine: Food Manufacturers

Your Innovative And Dependable Partner

Xinxiang Xingdou Machinery Co., Ltd. is mainly engaged in the field of powder slurry such as 5-600 mesh particle powder slurry. Has extensive experience in this field. Widely involved in pharmaceutical, chemical, metal, battery materials, abrasives, ceramics, pigments, coatings, food and other powder industries.Us has more than 70 employees, a factory area of more than 50,000 square meters, a number of advanced processing equipment, and domestic sales of 4 million US dollars. The proportion of old customers is about 60%The company adopts a number of advanced equipment to ensure product quality, high-efficiency production methods to ensure preferential prices, good after-sales service to ensure customer experience, rich experience to select professional equipment for customers, accept customization, and accept postal material test equipment.