Straight row sieve

Straight row sieve can also be understood as a special type of rotary vibrating sieve. Although the structure is different, the trajectory of the material is the same. The straight row sieve has its suitable scene, especially suitable for screening the possible foreign matter before some powder raw materials enter the production line.

For example, before using flour to make bread, it can effectively avoid lint on the bag, foreign matter during transportation, or flour agglomeration through an in-line sieve. Or wheat is made into flour through a series of processing. Before bagging, it needs to be sieved in a straight line to filter out foreign matter such as screws that may exist in the flour.

Common Applications

Straight row sieve-Screening experiment

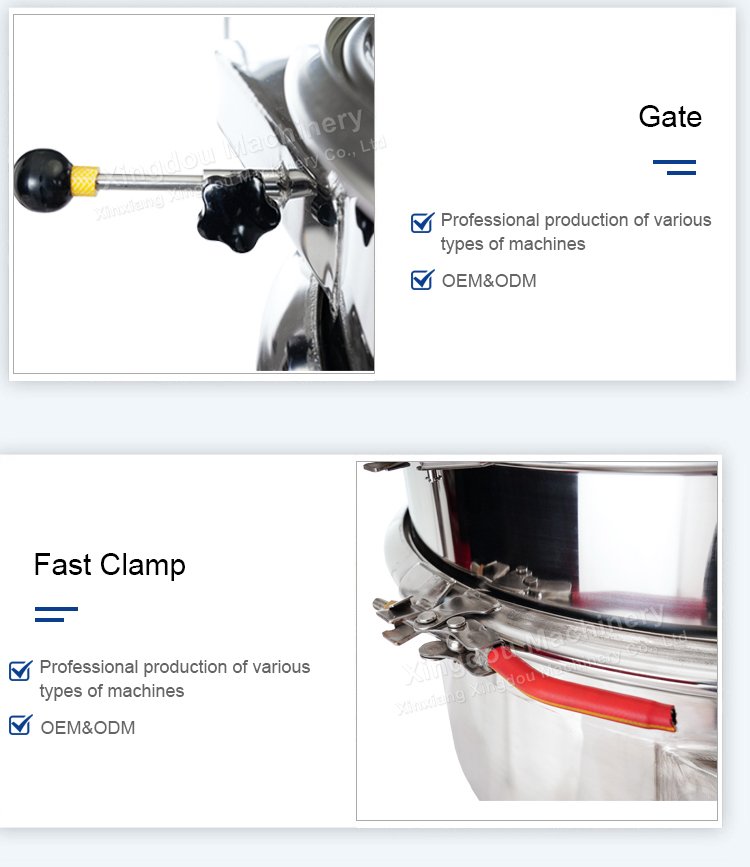

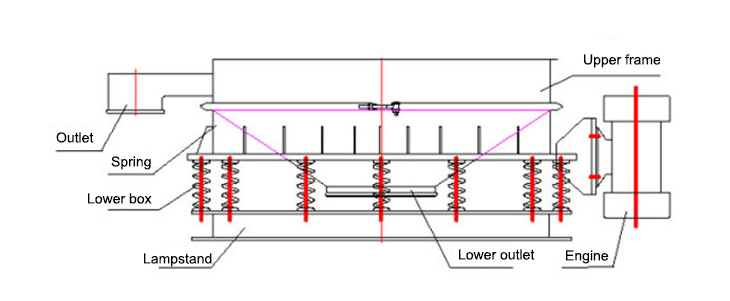

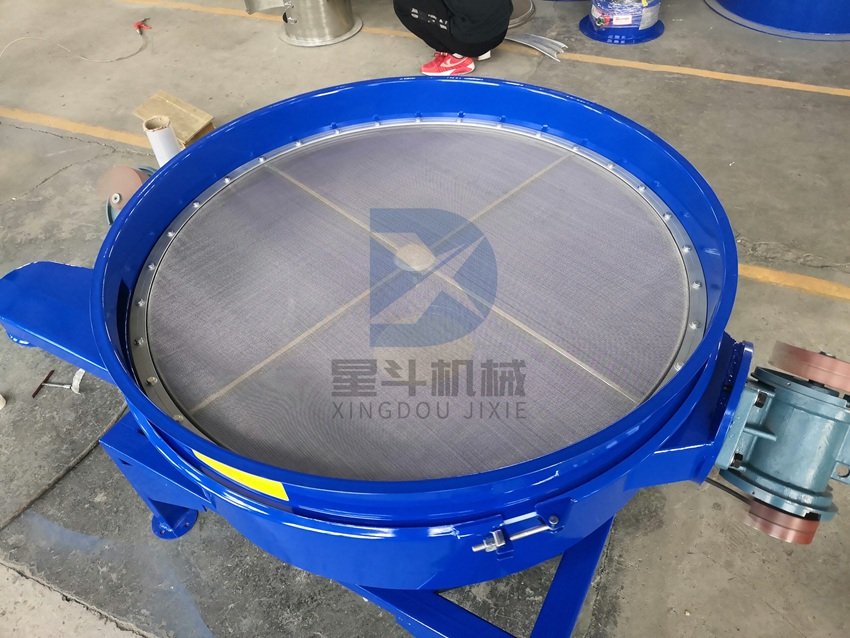

Structure of the Straight row sieve

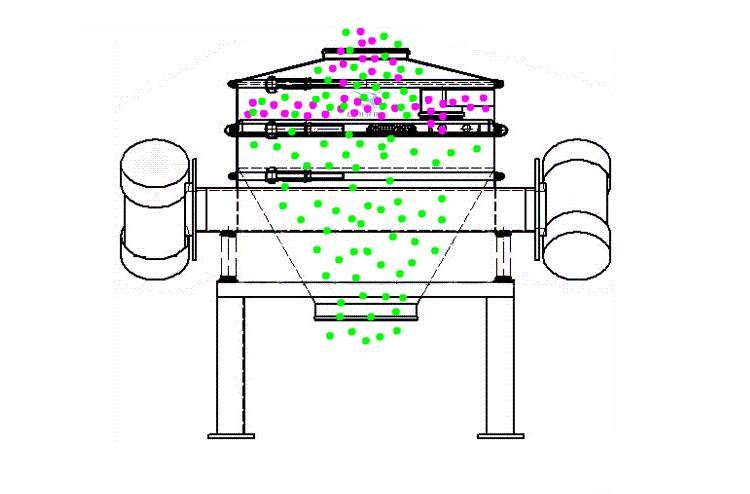

Working principle

The straight row sieve uses two sets of eccentric blocks at the upper and lower ends of the vibrating motor to change the rotating motion of the vibrating motor into horizontal, vertical, inclined, and centrifugal multi-force overlapping, and then transfer this force to the screen surface to complete the screening. Because of its special structure, it is very suitable for screening materials with little on-screen material and relatively large throughput. For example, sift out lumps in seasonings.

Product Parameters

| Straightsieve model | Motor model | Motor power | Voltage | Number of motors | Numberof motors | Equipment material |

|---|---|---|---|---|---|---|

| XDZ-600 | YZU3-4 | 0.18KW/0.18KW | 220-480V | 1500r/min | 1-2 pieces | Q235/304/316L |

| XDZ-800 | YZU3-4 | 0.18KW/0.18KW | 220-480V | 1500r/min | 1-2 pieces | Q235/304/316L |

| XDZ-1000 | YZU5-4/3-4 | 0.25KW/0.18KW | 220-480V | 1500r/min | 1-2 pieces | Q235/304/316L |

| XDZ-1200 | YZU10-4/5-4 | 0.55KW/0.25KW | 220-480V | 1500r/min | 1-2 pieces | Q235/304/316L |

| XDZ-1500 | YZU15-4/104 | 0.75KW/0.55KW | 220-480V | 1500r/min | 1-2 pieces | Q235/304/316L |