square gyratory screen

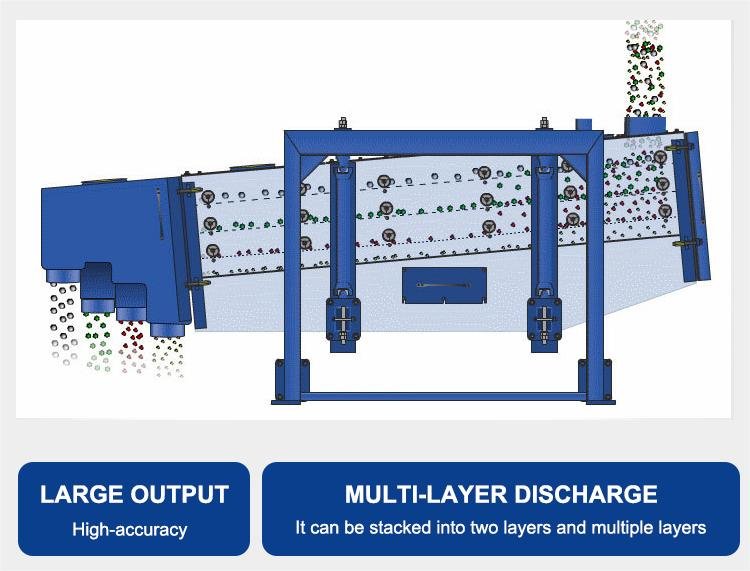

Gyratory screen is high-efficiency screening equipment specially designed for high-precision and large-volume production. It is widely used in chemical, non-ferrous metal, food, quartz sand, abrasive and other industries.

gyratory screen Common Applications

square gyratory screen experiment

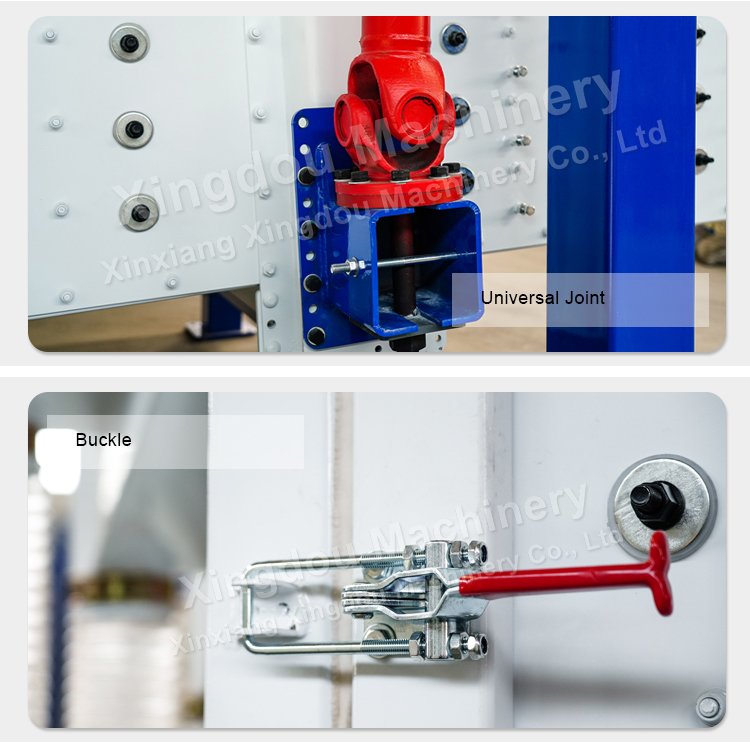

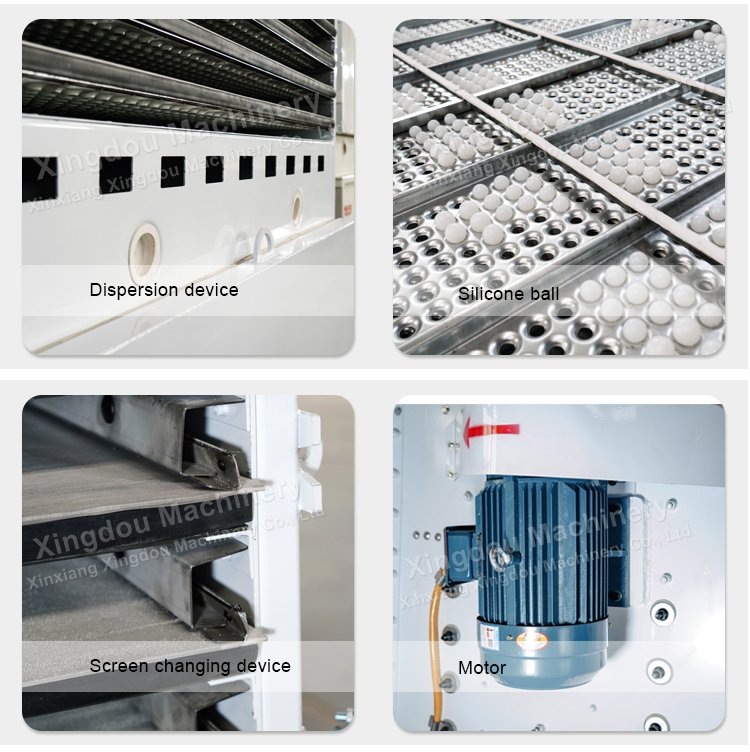

Structure of the square gyratory screen

gyratory screen Working principle

The square gyratory screen is the box responsible for screening and is suspended by four universal joints, and the motor drives the eccentric weight to rotate. Regular swing to achieve screening. The speed is 180-260 rpm, and the stroke is 25-60 mm.

Product Parameters

| Square swing screen model | Motor type | Motor model | Motor power | Voltage | Motor speed | Number of motors | Number of plies |

|---|---|---|---|---|---|---|---|

| FYBS-1535 | motor | YE2132S-4 | 5.5KW | 220-480V | 1440r/min | 1 | 1-10 floors |

| FYBS-2040 | motor | YEH132M-4 | 7.5KW | 220-480V | 1440r/min | 1 | 1-10 floors |