linear vibrating screen

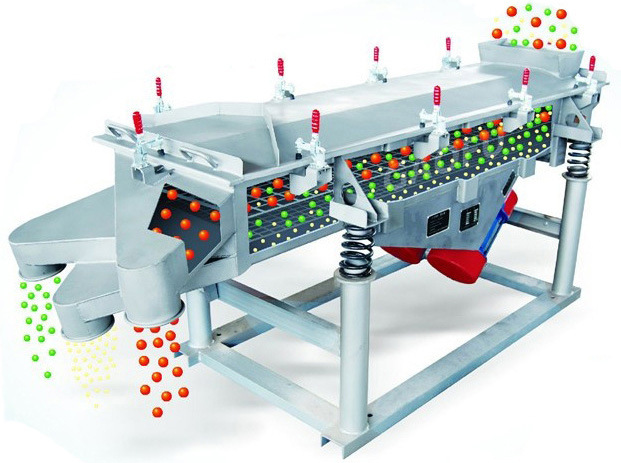

The linear vibrating screen is driven by two vibrating motors. The two vibrating motors move synchronously and in opposite directions, so that the materials on the screen move forward regularly, and the oversize and undersized materials of several specifications are produced through the multi-layer screen and are discharged from their respective outlets, to achieve the effect of screening.

Common Applications

Linear Vibrating Screen-Screening experiment

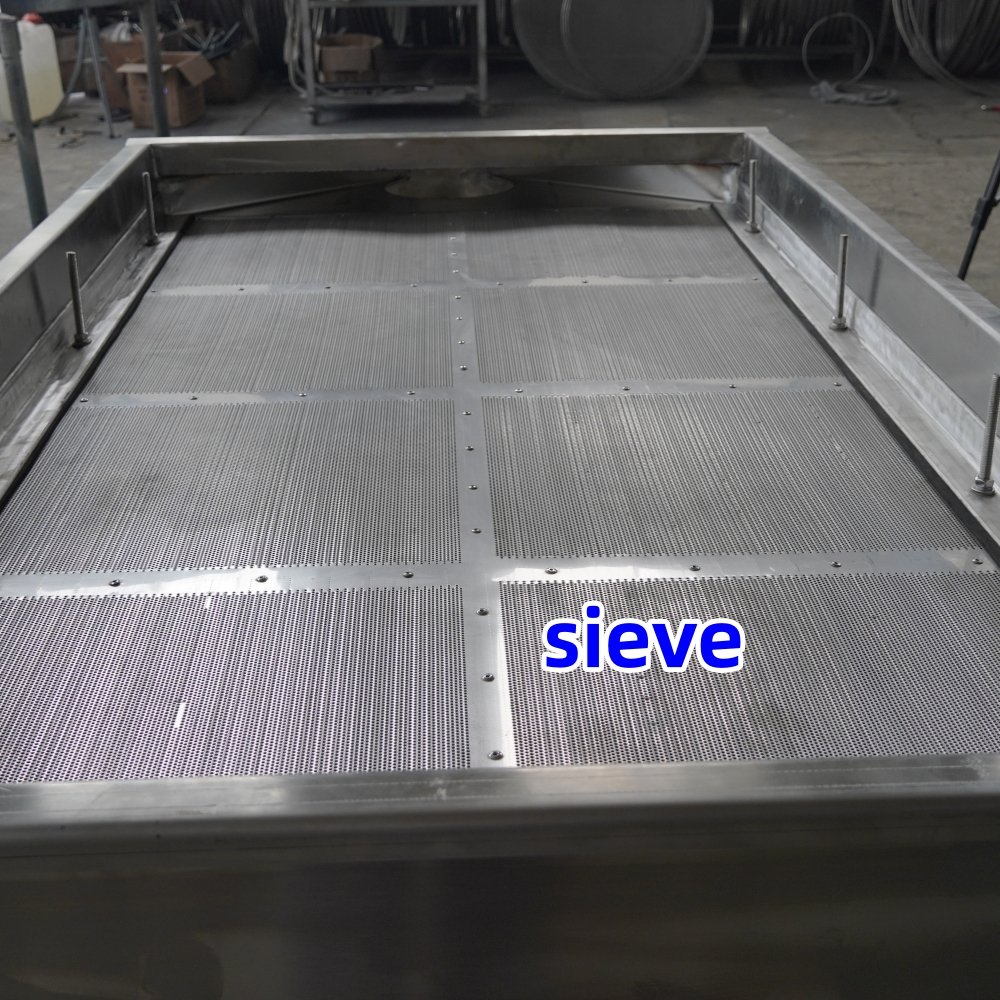

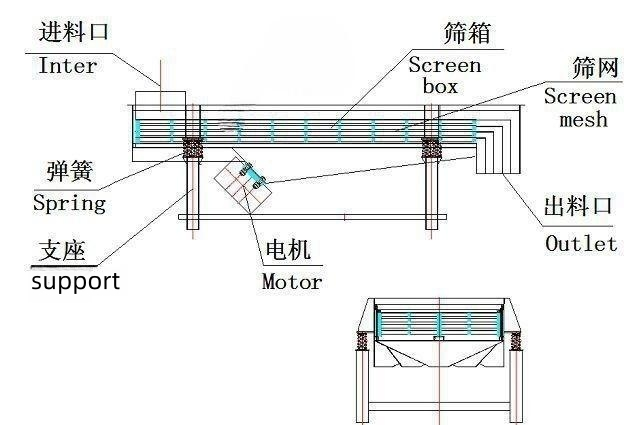

Structure of the Linear Vibrating Screen

Working principle

Product Parameters

| model | Mesh size(mm) | Material particle size(Mesh) | Screen inclination(°) | amplitude(mm) | layers | power(kw) |

|---|---|---|---|---|---|---|

| XDZ520 | 500*2000 | (5-105) | (-3°~7°) | (2-7) | (1-4) | 2*(0.37~0.75) |

| XDZ525 | 500*2500 | 2*(0.37~0.75) | ||||

| XDZ530 | 500*3000 | 2*(0.55~1.1) | ||||

| XDZ1020 | 1000*2000 | 2*(0.55~1.1) | ||||

| XDZ1025 | 1000*2500 | 2*(1.1~1.5) | ||||

| XDZ1030 | 1000*3000 | 2*(1.1~1.5) | ||||

| XDZ1035 | 1000*3500 | 2*(1.5~2.2) | ||||

| XDZ1225 | 1200*2500 | 2*(1.5~2.2) | ||||

| XDZ1230 | 1200*3000 | 2*(1.5~3) | ||||

| XDZ1235 | 1200*3500 | 2*(1.5~3) | ||||

| XDZ1530 | 1500*3000 | 2*(2.2~3) | ||||

| XDZ1535 | 1500*3500 | 2*(2.2~3) |