Abrasive Industry

Abrasives are sharp and hard materials used to grind softer materials. They are widely used in the hardware and abrasive tool manufacturing industry, jade and gemstone polishing industry, ceramic industry, metal mold casting industry, glass industry, machinery industry, Refractory industry, electronics industry, steel industry, etc. Different industries have different requirements for the material, characteristics, hardness, and particle size of abrasives. Among them, distinguishing the particle size is the main function of the vibrating screen.

Screening in the abrasive industry is an industry that is easier for vibrating screens to screen. Most abrasives are non-oily and non-absorbent, when the vibrating screen sieves abrasives, only the following points are required.

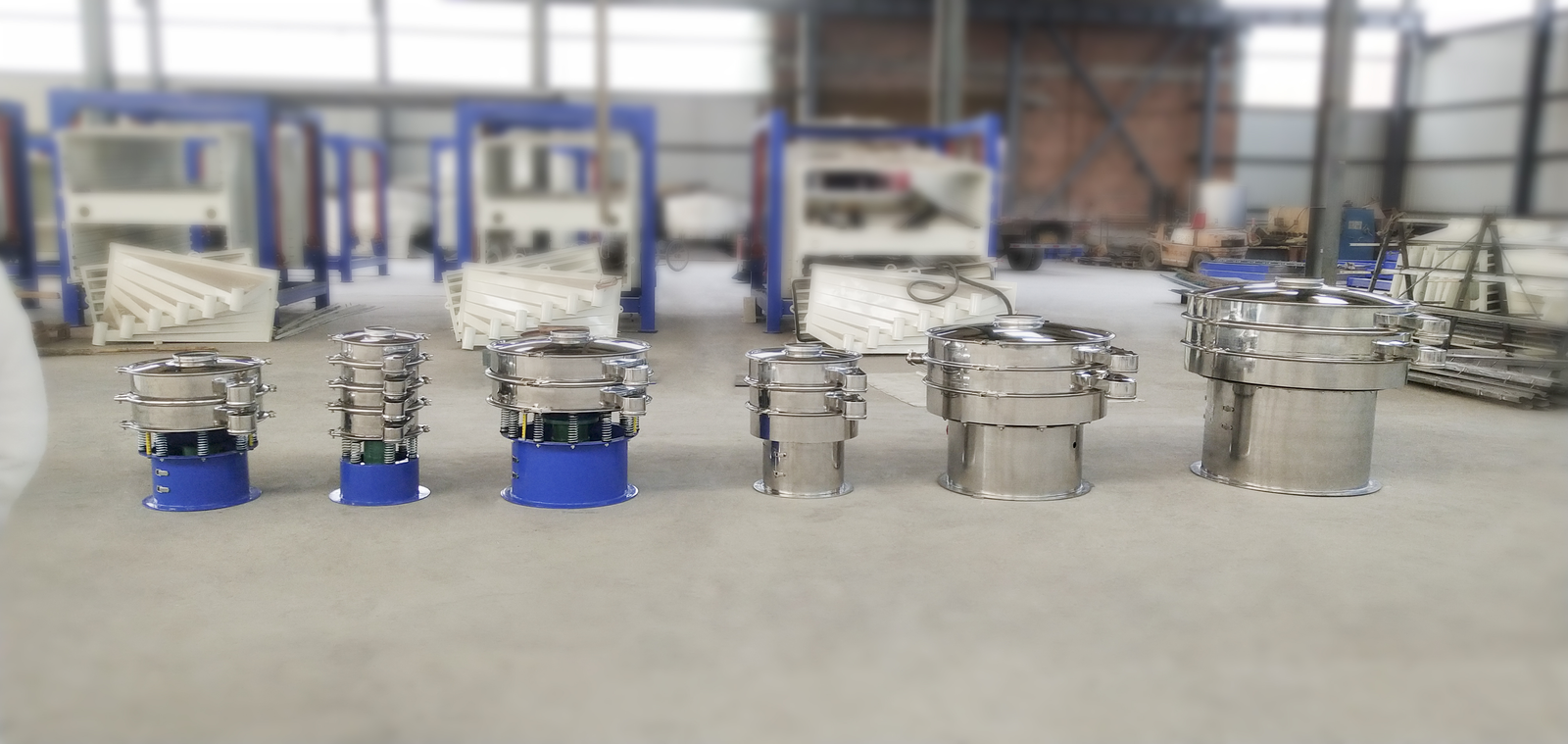

1. Select the appropriate vibrating screen model to meet the customer’s requirements for output

2. According to the different powder particles sieved by customers, choose the ultrasonic cleaning method or the bouncing ball cleaning method

3. Protect the screen: Usually, the abrasives are relatively hard. The abrasives fall directly from the feed port to the screen, and impact the screen in one place for a long time, which is easy to cause damage to the screen. We usually install a buffer device at the feed port of the equipment. to protect the screen

There are many types of abrasives, our company has rich experience, welcome your consultation.