vacuum feeder machine: food manufacturers

With the development and progress of society, more and more attention is paid to food safety, which puts forward higher requirements for food manufacturers. In some deep-processed food factories, it is often necessary to mix a variety of food raw materials to make specific food or raw materials. , How to transport a variety of food raw materials to the designated position safely and without pollution, the vacuum feeder machine can help you.

Customer requirements:

Our company has a customer who is in the food processing industry. After the customer visited our company and visited our factory, he hoped we would recommend a piece of equipment to him. The customer’s requirements are:

- The conveying equipment is required to be conveyed under sealed conditions and cannot be polluted

- There is not much space on the customer site, and I hope to choose a small device

- The downstream equipment of the customer conveyor is a mixer, and the conveying height is 2.7 meters high

- The customer needs to send various raw materials, and most raw materials can be transported at 600 kg per hour. They are all sent to the mixer in batches through this conveying equipment to complete the mixing.

- The customer’s feeding method is manual feeding, which should be convenient for workers to operate

Project solution

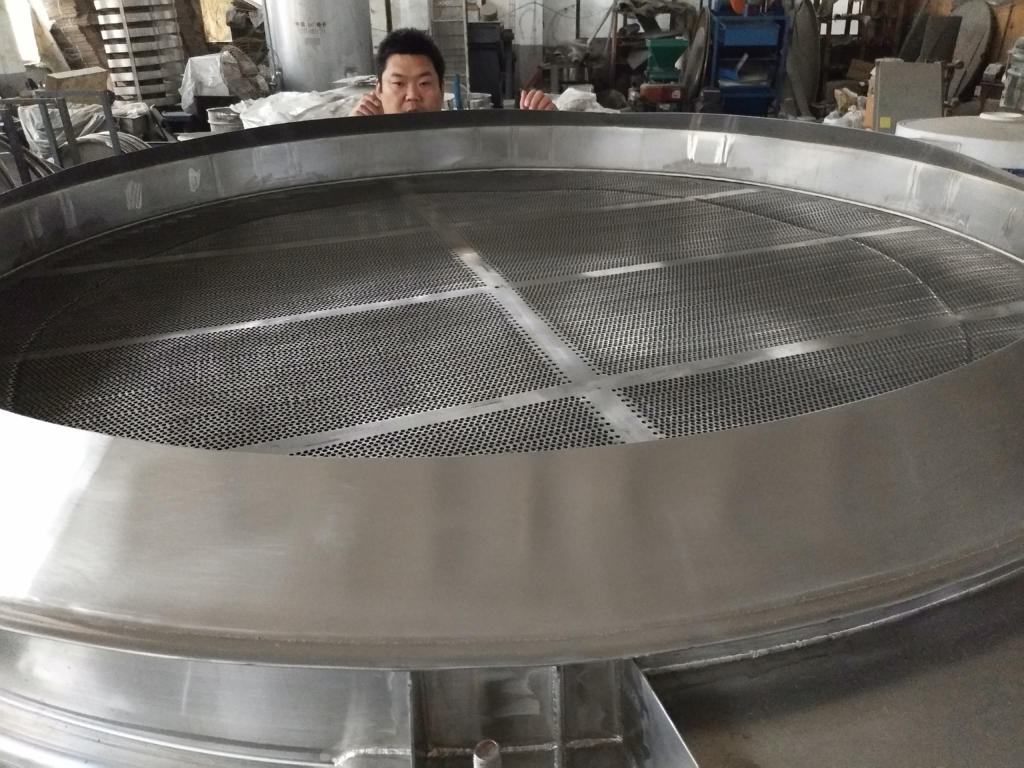

The solution given by our company is the vacuum feeder machine zk-4 type equipment, customized for the customer, changing the feeding port to a small V-shaped silo

Advantages of vacuum feeding machine

- Vacuum negative pressure conveying, no pollution

- The conveying pipeline can be placed according to the customer’s site and can be turned

- The parts in contact with materials are all food-grade materials

- Conventional powder materials can be transported by vacuum feeder, with a wide range of applications

- Accept customization, and products can be customized according to customer’s on-site needs

- Simple operation and easy maintenance

client feedback

Customers are very satisfied with our products after using them. This equipment meets all the needs of customers, and the equipment has only changed the filter element a few times during long-term use, and the quality is very stable.

Product Use

No posts