Tumbler Screening Machine: EPP industry solution

EPP material: It is non-toxic and tasteless, has impact resistance, wear resistance, and corrosion resistance, and has the advantages of heat preservation, flame retardancy, and oil resistance. It is widely used in the construction industry, household industry, toys, automobiles, light industrial food, etc. Belongs to high-end materials.

Customer requirements:

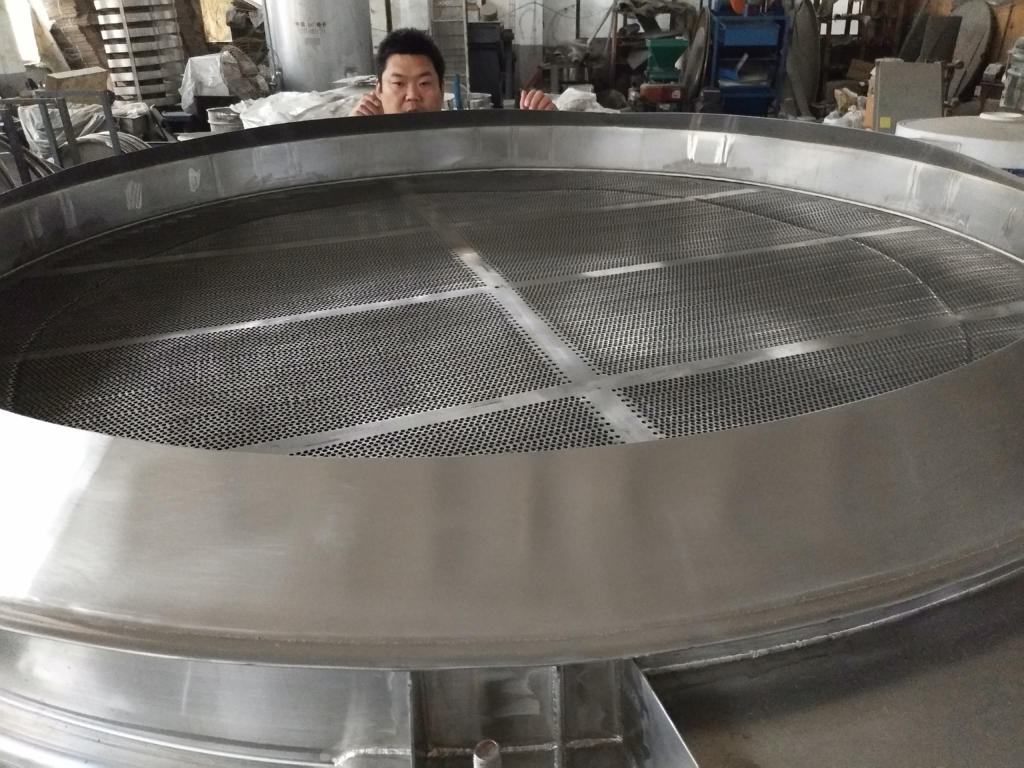

- Three layers of the screen: 5mm, 2.8mm, 2.3mm.

- The mesh is circular.

- Accuracy requirement ≥98%.

- Capacity requirement ≥ 4 cubic meters.

- The quality of the equipment is stable.

- 304 stainless steel material, does not pollute the material.

- Open design for easy feeding.

- The discharge port is extended to facilitate material receiving.

Project details

During the production process of EPP material, it needs to be foamed many times, and a few particles fail to foam, and there will be uneven foaming, no successful foaming, or adhesion after foaming, which needs to be removed by vibrating screen in time, but EPP material is a thermoplastic material with light specific gravity, and its density is generally 17-100kg/m³. This creates a big problem for sieving.

For materials with very light specific gravity, it is difficult to achieve an accuracy of more than 90% in the screening process, because the working principle of the general vibrating screen is to rely on the vibration of the equipment to screen, and it is difficult for particularly light materials to fully contact the screen under the action of vibration.

Project solution

The motion trajectory of the Tumbler Screening Machine imitates manual screening. It mainly screens materials through the shaking and swinging of the equipment. Every movement of the equipment will cause the materials of the same weight and volume to gather in layers. Secondly, the materials that touch the screen will not move away from the screen due to vibration, but will fully contact. The three-layer stainless steel Tubmler Screening Machine perfectly solves the customer’s problem.

At present, 40% of the EPP industry in China is our company’s Tumbler Screening Machine.

Precautions for the use of Tumbler Screening Machine

The location of the placement should be firm

Depending on the model, the weight of the circular swinging screen is between 650 kg and 2000 kg. The equipment will be heavier after the materials are put in. All places required to be placed must be strong and stable, and it is best to place them on the ground.

If it is placed on a shelf in mid-air, long-term shaking will cause metal fatigue of the shelf, and safety accidents may occur.

The placement position should be horizontal

the circular swinging screen will adjust the operating angle, shaking range, and swinging range of the equipment according to the different materials at the factory. If the location itself has an inclined angle, it will directly affect the screening effect.

Lubricating oil filling

No. 3 Potassium-based grease (ZL-3) must be replenished once every 500 hours of equipment operation. The replenishment amount has been replaced by the old lubricating oil at the oil nozzle.

Check the screen

Check the screen daily for wear and tear. After replacing the screen, tighten all loose screws.

Abnormal noise

When the circular swinging screen is working normally, the noise is less than 75 decibels. If there is any abnormal noise, please stop the operation as soon as possible, check the cause of the abnormal noise, and contact us in time if it cannot be resolved.