Spiral Elevator case: monosodium glutamate

There are many types of lifting equipment, different materials, different scenarios, different requirements, and different requirements for hoists.

This is a customer who produces condiments – monosodium glutamate. Due to its special production process, monosodium glutamate will cause a problem, that is after the production of monosodium glutamate is completed and before it is bagged, the temperature of monosodium glutamate is higher than the ambient temperature, and it cannot be packaged immediately Machine-sealed bags. At the same time, the customer’s production line is very large, and the finished product is 8 tons per hour. It takes no time and space to cool down naturally. At this time, a mechanical device is needed to cool down-a Spiral Elevator.

Customer requirements:

- While lifting the material, the shape of the monosodium glutamate should not be damaged

- The conveying capacity is 8 tons per hour

- While conveying the material, it is necessary to cool the temperature of the material from about 55 degrees to room temperature

- The lifting height is 7 meters, and the discharge port is 7 meters from the ground. The feed inlet is 1 meter from the ground

- The contact material is made of 304 stainless steel

- The quality of the equipment is stable and the operation is simple

- Customized content: a chute should be added to the discharge port, the length of the chute is 1.2 meters, the width is 300MM, and it is connected with the downstream packaging machine

Project solution

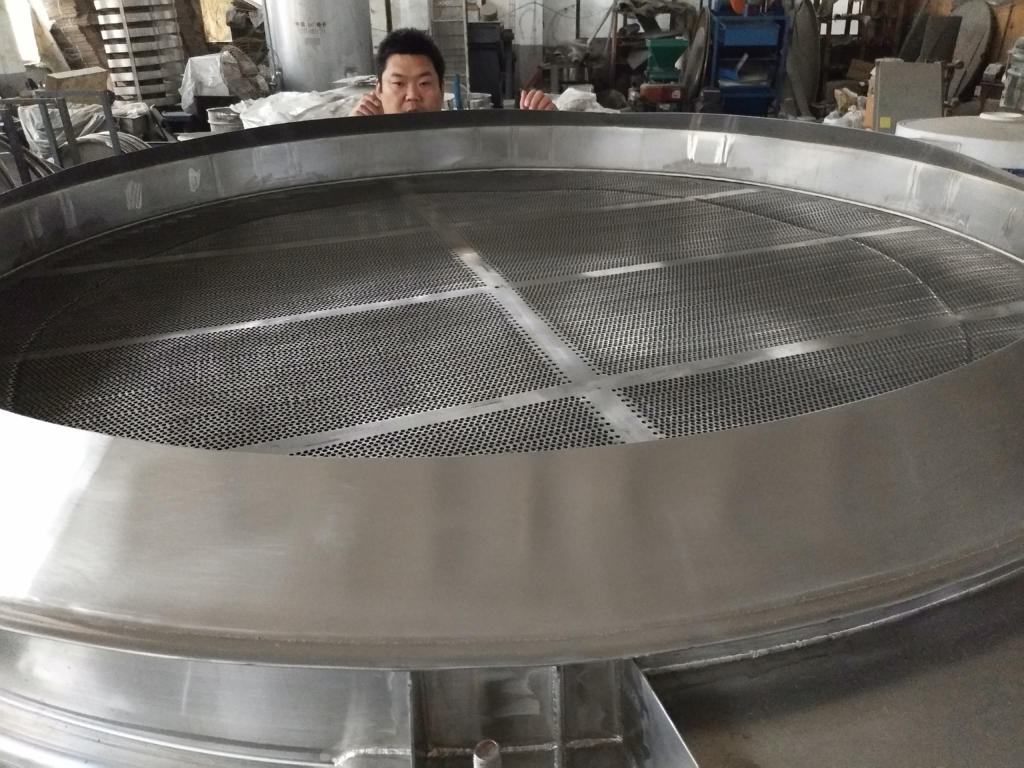

Our suggestion to customers is equipment selection: Spiral Elevator. Model: Diameter 1200, Customization: Add a water cooling system and an air cooling system on the Spiral Elevator to ensure that the material can be cooled from 55° to normal temperature.

Advantages of Spiral Elevator

- The most important thing is to cool down or heat the material while conveying the material

- The floor space is small, and materials can be lifted vertically. The conventional model only needs an area of 1.5 meters wide and 1.5 meters long to be installed

- Do not destroy the original shape of the material while conveying, for example, it is very suitable to lift and convey shredded tobacco in cigarettes

- Easy to operate and maintenance-free

- stable quality

- accept customization

client feedback

After the customer has used it, the effect is very good, and it can help the customer to produce continuously. At the same time, the height of the customized equipment can be transported to the feeding port of the packaging machine.