ultrasonic vibrating screen

Ultrasonic vibrating screen can be understood in this way: the ultrasonic system can be regarded as an independent system, and the vibrating screen equipment is also an independent equipment. For the ultrasonic vibrating screen, an easy-to-understand example: battery power system + bicycle = electric bicycle.

ultrasonic vibrating screen principle

The ultrasonic system has the characteristics of high frequency and low amplitude. During the sieving process, the ultrafine powder receives a huge ultrasonic acceleration, so the material on the sieve surface is intermittently suspended, and the ultrafine powder is effectively suppressed. The characteristics of adhesion and adsorption solve the screening problems of strong adsorption, easy agglomeration, high static electricity, high fineness, high density, and light-specific gravity.

The working principle of the ultrasonic system on the vibrating screen

the ultrasonic system converts the two-phase electric energy into 18KHZ high-frequency electric energy through the power box, inputs it into the ultrasonic transducer, and converts it into a frequency of 38KHZ and an amplitude of 10 microns- -60 microns of mechanical vibration. To achieve the purpose of auxiliary screening.

Ultrasonic system

Vibrating screen

Application

1: When screening powder materials between 80 mesh and 150 mesh, the addition of an ultrasonic system is an effective auxiliary function. When screening powder materials between 150 mesh and 500 mesh, adding an ultrasonic system is the main function.

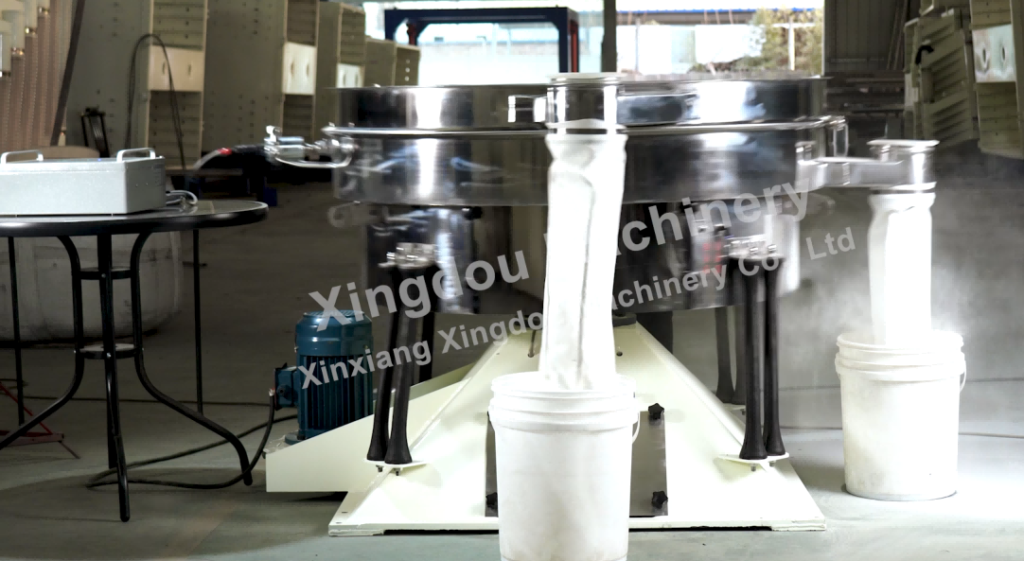

2: All circular vibrating screens can be ultrasonic systems, including Tumbler Screening Machine, rotary vibrating screens, Direct discharge sifter, Test Sieve

3: The addition of the ultrasonic system has significantly improved the screening accuracy and output

4: When the screened material contains oil, or has static electricity, the material is absorbent, the material is easy to agglomerate, or the specific gravity is greater than 2.0, the effect of the ultrasonic vibrating screen is much higher than that of the ordinary vibrating screen.

Common devices combined with ultrasound systems

Ultrasonic Rotary Vibrating Sieve for Fine

Ultrasonic Rotary vibrating screen is mainly used for fine powder, granules, liquid screening, and filtration, Powder, granules can be accurately divided into 2-5 grades, sorting accuracy can reach more than 98%, and liquid filtration up to 25 microns.

Ultrasonic Circular Vibrating Screen

Rotary vibrating screen is mainly used for powder, granule, liquid screening and filtration, powder, granules can be accurately divided into 2-5 grades,sorting accuracy can reach more than 98%, liquid filtration up to 25 microns.

Ultrasonic Test Sieve

The characteristics of the direct discharge sifter are that the materials that have passed through the screen can be quickly excluded, it is most applicable to the scene is: in the raw materials into the production system, before the raw materials are screened to prevent the raw materials in the transportation or open the package when the falling foreign objects into the production system (such as making pastry production line, need a lot of flour, in the open flour bag, may bag debris into the production system), or in the finished materials for the system), or before the finished material is packaged, screen for possible foreign objects (such as the production line for seasonings, screen for screws or lumps dropped by upstream equipment) to ensure that all products are qualified.

Please contact us for specific material screening details, and we will give professional advice.