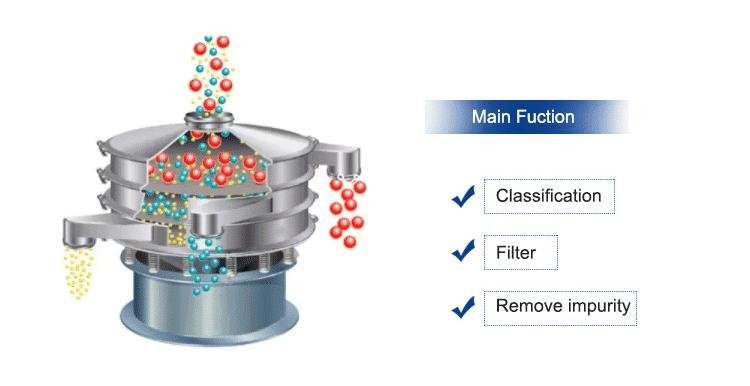

rotary vibrating screen

The rotary vibrating screen is a high-precision fine powder screening machine, suitable for 5-500 mesh powder, and liquid up to 635 mesh. It has low noise and high efficiency. It takes 3-5 minutes to quickly change the screen. It has a fully enclosed structure and is widely used in the chemical industry, food industry, pharmaceutical industry, etc. All kinds of powder industries can screen any particles, powders, and mucus within a certain range. It is a cost-effective product.

Common Applications

rotary vibrating screen-Screening experiment

Structure of the rotary vibrating screen

Working principle

Product Parameters

| Model of rotary vibrating screen | Motor type | Motor model | Motor power | Voltage | Motor speed | Equipment material | Number of plies |

|---|---|---|---|---|---|---|---|

| XD-400 | Vertical vibration motor | YZUL3-4 | 0.25KW | 220-480V industrial three-phase power | 1500r/min | Q235/304/316L | 1-2 floors |

| XD-600 | Vertical vibration motor | YZUL5-4 | 0.55KW | 220-480V industrial three-phase power | 1500r/min | Q235/304/316L | 1-4 floors |

| XD-800 | Vertical vibration motor | YZUL8-4 | 0.75KW | 220-480V industrial three-phase power | 1500r/min | Q235/304/316L | 1-4 floors |

| XD-1000 | Vertical vibration motor | YZUL10-4 | 1.1KW | 220-480V industrial three-phase power | 1500r/min | Q235/304/316L | 1-4 floors |

| XD-1200 | Vertical vibration motor | YZUL15-4 | 1.5KW | 220-480V industrial three-phase power | 1500r/min | Q235/304/316L | 1-4 floors |

| XD-1500 | Vertical vibration motor | YZUL30-4 | 2.2KW | 220-480V industrial three-phase power | 1500r/min | Q235/304/316L | 1-4 floors |